Description

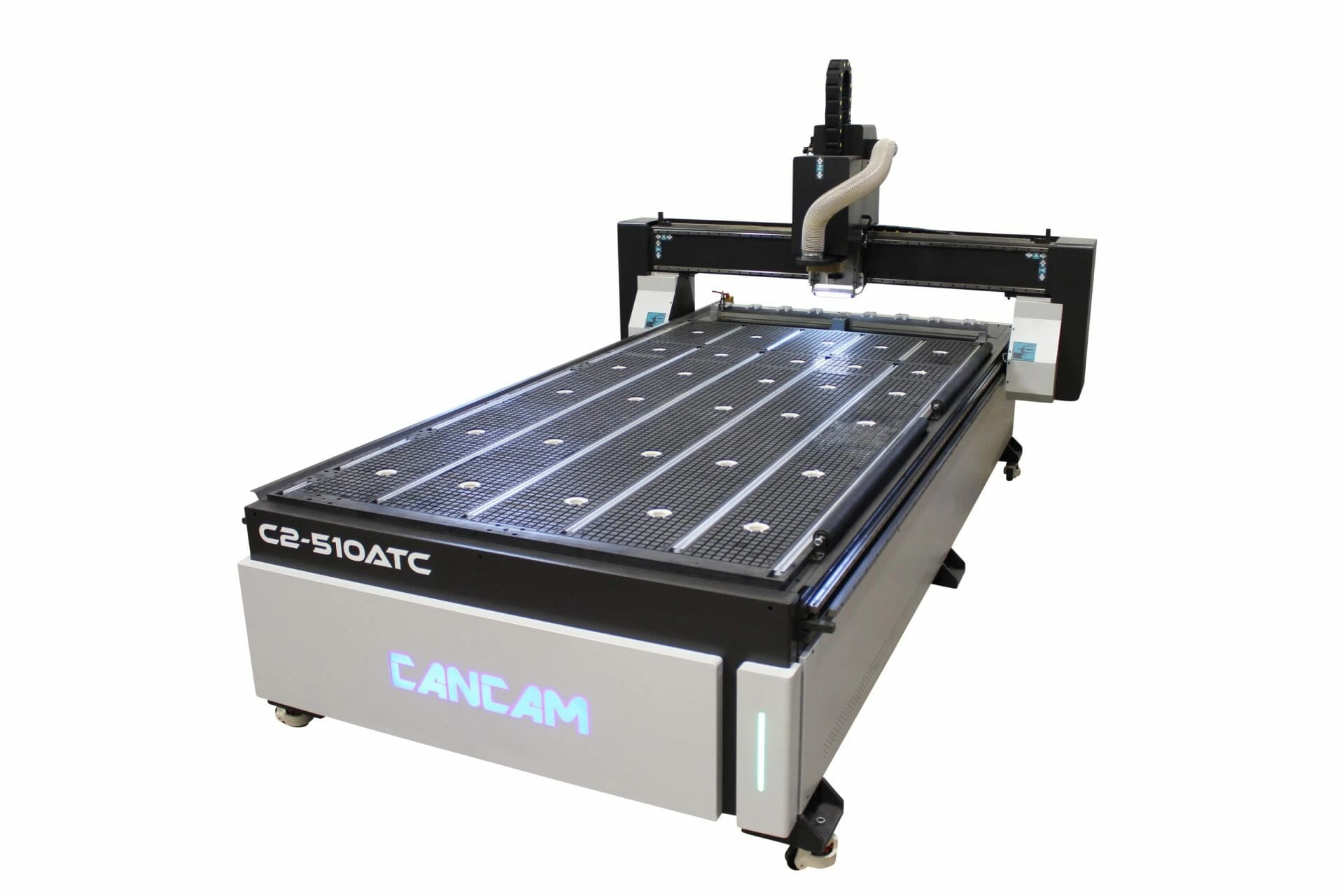

This machine’s rugged vibration-reducing design and durability allows the spindle to achieve speeds of up to 24000 RPM and IPM feed rate up to 1200. This ensures the finishing on the material of your choice will be perfect, with minimized cutting time. Minimized cutting time allows you to complete jobs faster thus maximizing your output.

The C2 series is designed to use the latest state of the art Masso controller. The Masso controller allows you to use both fixed and mobile auto tool touch offs, ensuring you save time when switching out tools at any point during the production.

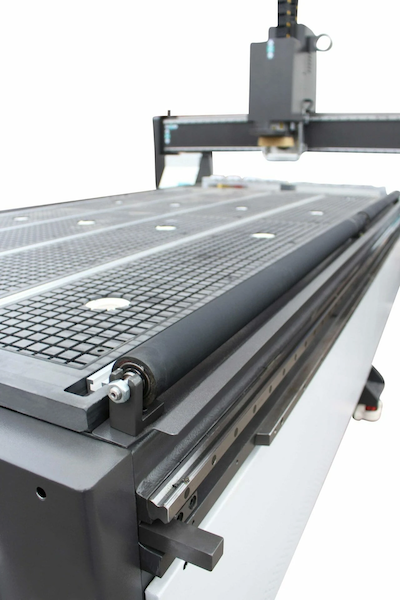

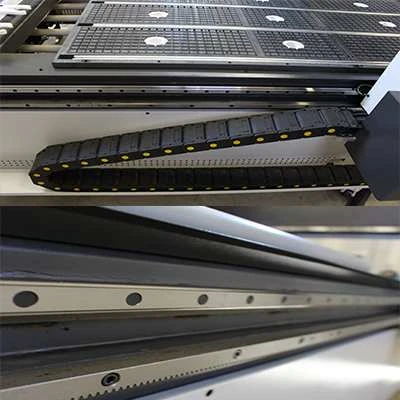

The C2 series commercial CNC routers come with closed loop servos, linear guides, helical rack and pinion motor mounts along with planetary gear reducers making this machine a high quality build with tighter tolerances typically found in ball screw machines without compromising cutting speed.

The carbon alloy steel gantry and prestressed frame are nearly 1/2” thick along with the 1” milled gantry support posts that contribute to reducing vibration without compromising accuracy.

Flexibility in the product offering is available through increased gantry heights up to 15” clearance, variety of table top options, laser diode option, rotary lathes.

This model is available in a variety of sizes ranging from 4’ wide to 30’ long.

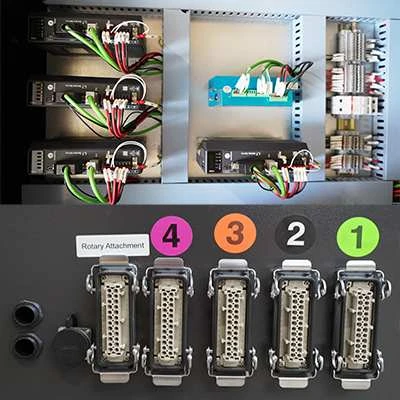

This industrial CNC router is available in single phase or 3 phase. Which means you can put in just about any residential garage if needed.

The combination of the engineering and quality components built into this design ensure that you get the ‘Up in class, Down in price’ that CanCam is committed to delivering to all its customers.

Product Features

|

Single phase or 3 phase power The C2 series is built to spec for either single phase or 3 phase making this an extremely flexible machine for installation in comercial, industrial or residential applications. |

|

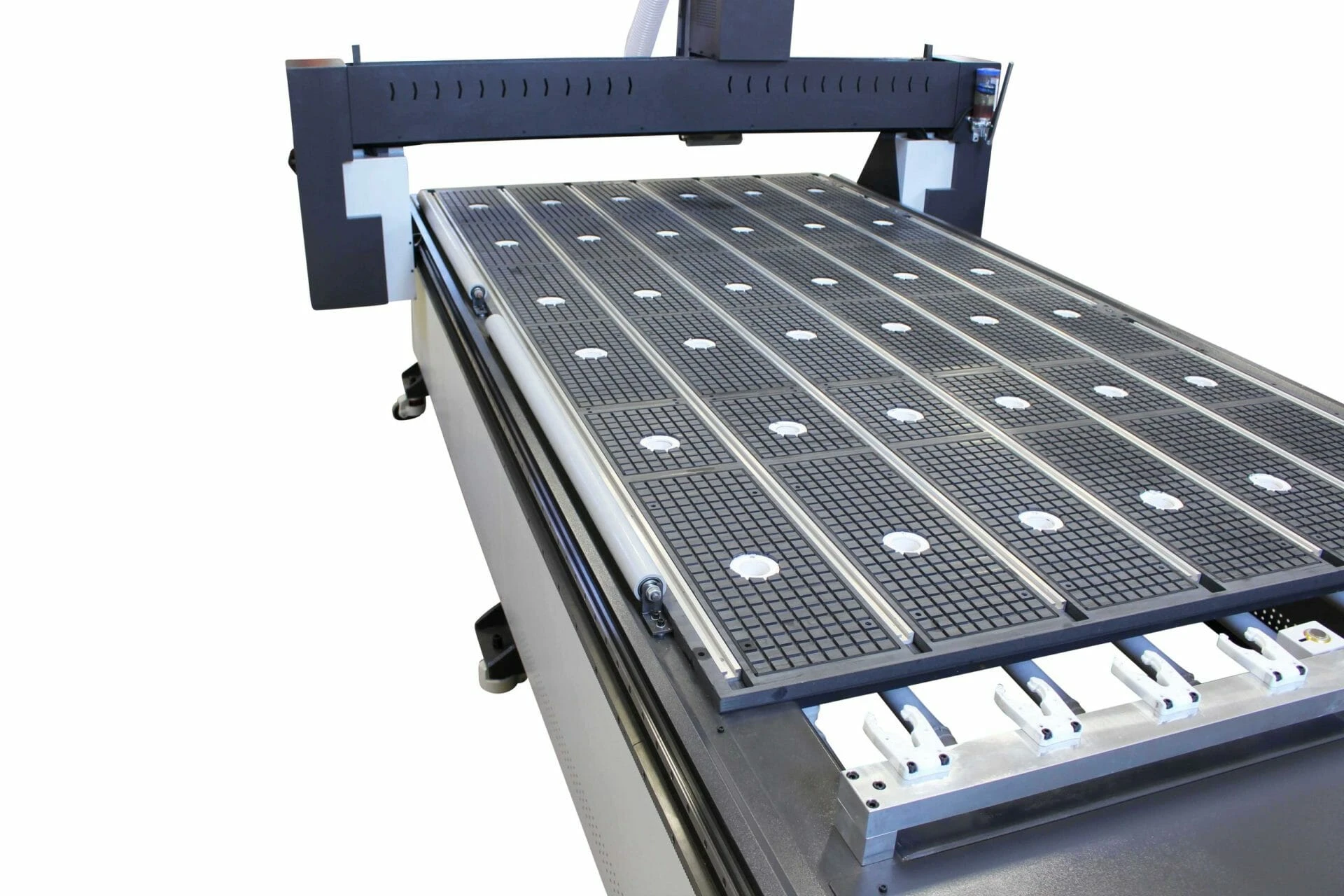

Pneumatic Or Electric Solenoid actuated vacuum zones Control isolated vacuum zone locations with the press of a button. |

|

Two calibrators A unique design feature, fixed and mobile calibration, is standard for all C series CanCam CNC machines. Our C series equipment come with two calibrators to allow for oversized tool calibration, mobile calibration for odd sized materials and to any location you choose. |

|

Easy sheet rollers Roll your sheets on with ease. |

|

Integrated lubrication system Making maintenance simple and easy. |

|

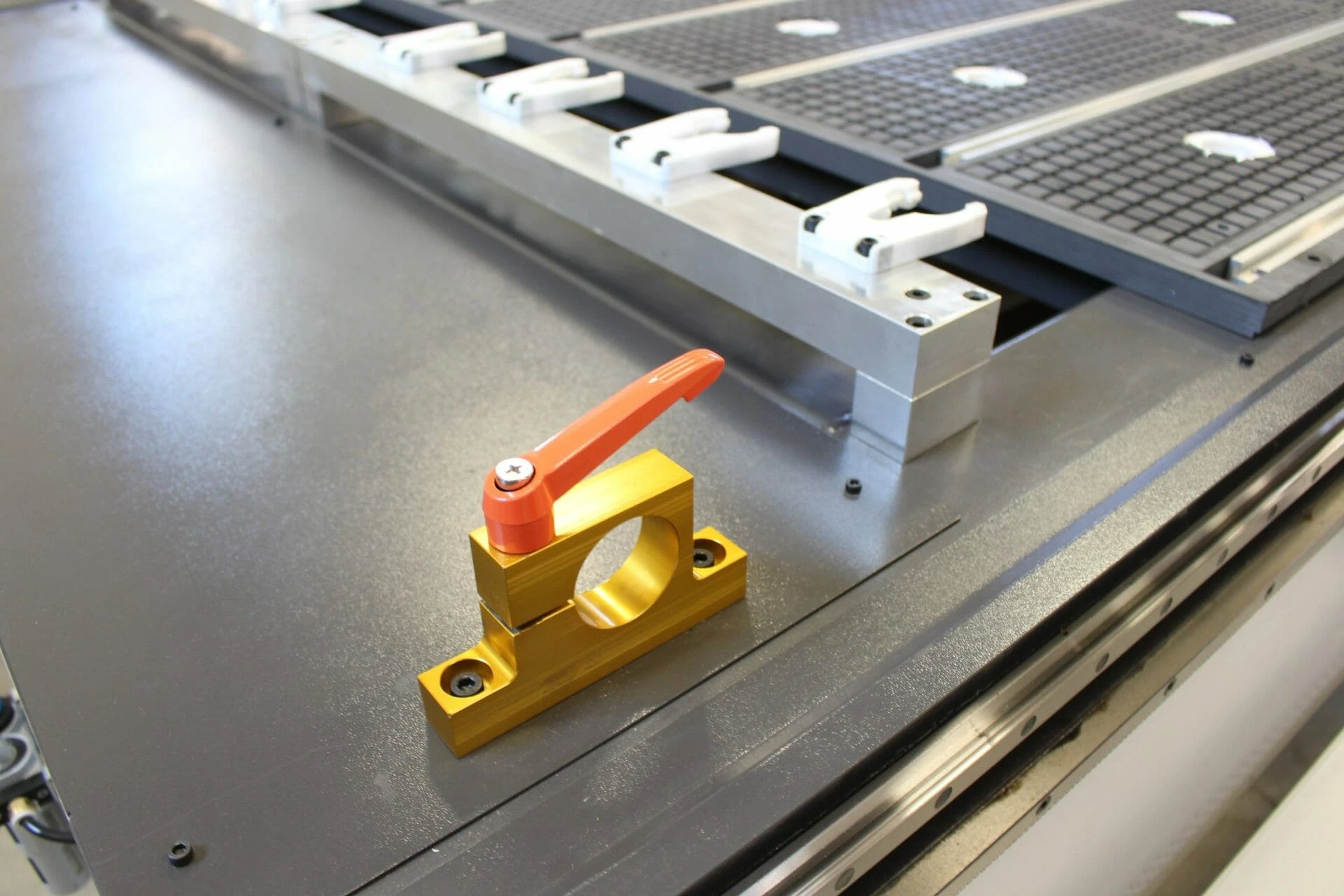

Tool change fixture On the rear of the CNC router bed you have a fixture to make it easy to tighten your collet on the tool holder. |

|

Low maintenance The sealed motion components, enclosed cable carrier, linear rail covers, spindle cover and side gantry covers on the CNC router are designed to limit exposure to dust and debris. Minimizing the need for maintenance and frequent cleaning. |

|

Pop up location pins Pnuematic pins to assist you with your workpiece alignment. |

|

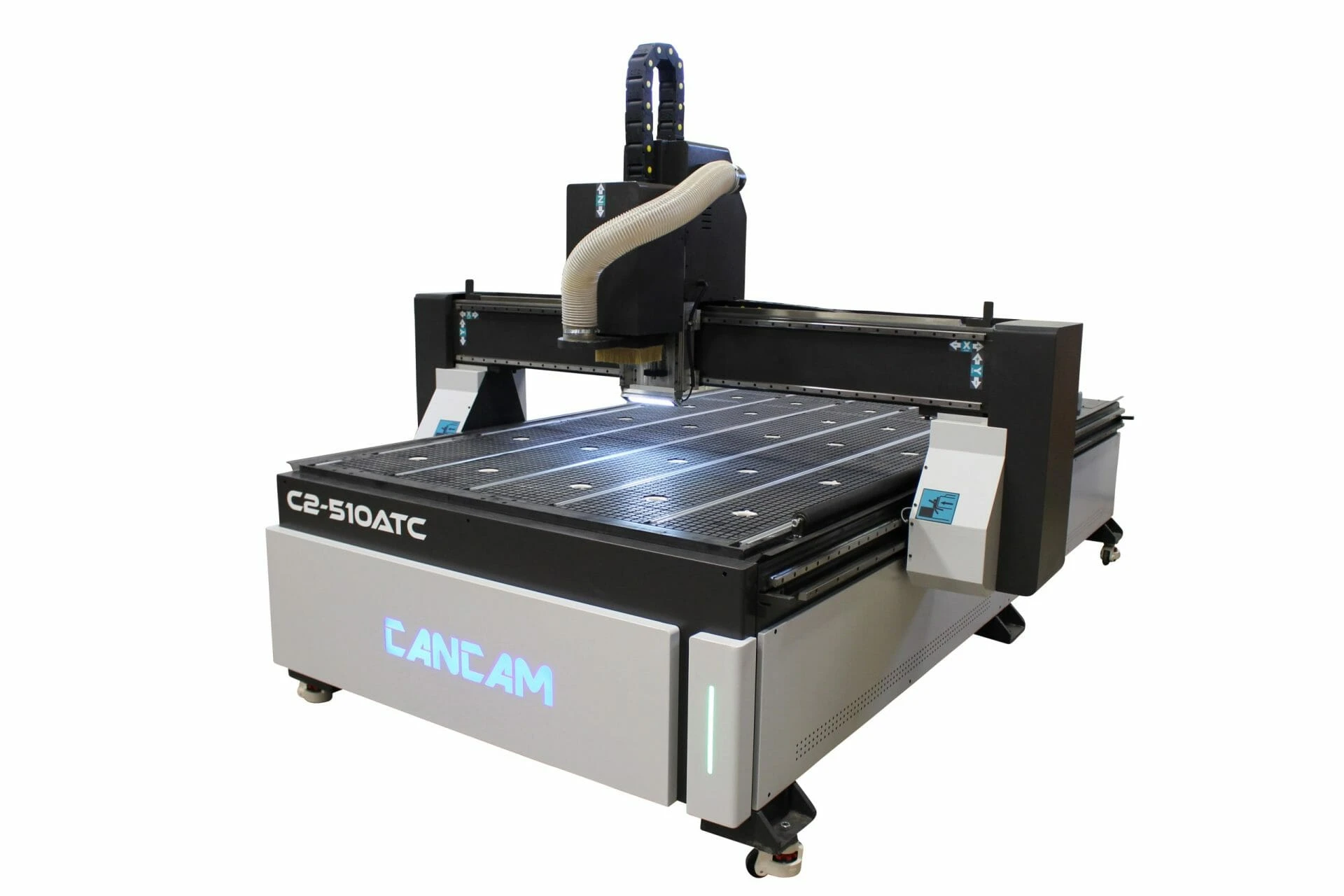

LED lights Bringing all your projects to light before they leave the table. Allowing for inspection of your work as it is being machined. |

|

Castors for ease of mobility With a light push you can reposition your CNC router where needed. |

|

Built in rotary plug Each C2 is outfitted with a spare servo driver allowing to add a plug & play rotary lathe to your equipment if needed. |

|

Quick release tool holder For a quick swap to a new tool, press the button and the tool pop out. |