Ever since we founded GRIT Automation in 2018, we have heard countless stories from teachers and administrators about the injuries and near-injuries that they have witnessed during their teaching careers. Recently, one particular story caught my attention, and immediately sent us into the lab to engineer a solution:

A post-secondary student was working in the welding lab, and was about to use an oxy-acetylene torch. Unbeknownst to him, someone had left an oxygen tank open earlier in the day, and when he used the igniter, it threw a flame across the room as it ignited the gas. Fortunately, this was one of those near-injuries, but we recognize that the results could have been disastrous. We immediately took action to manufacture a solution for these types of situations, and help minimize the danger and potential for injury. As a result, myself and the GRIT team created the GRIT Gas Control System.

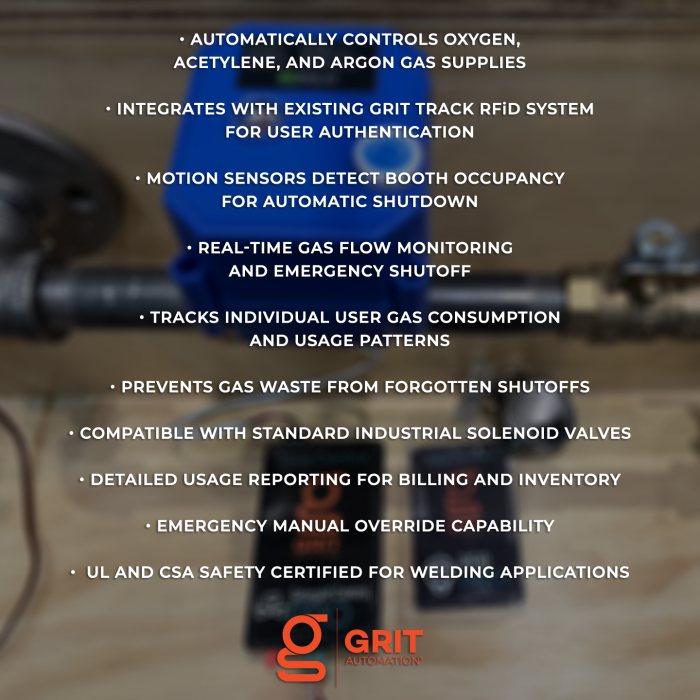

The GRIT Gas Control System revolutionizes welding safety and efficiency by seamlessly integrating with GRIT’s proven automation technology. Building on GRIT’s robust user authentication and tracking capabilities, this system provides unprecedented control over welding gas supplies while collecting valuable usage data.

Like other GRIT devices documented in the manual, the Gas Control System connects to the GRIT Hub through the mesh network, enabling real-time monitoring and control. The system leverages GRIT Track’s existing user management features, allowing administrators to set specific permissions for different gas types and maintain detailed usage logs per user.

The system employs industrial-grade solenoid valves that connect to oxygen, acetylene, and argon supply lines. When users authenticate with their GRIT Track RFiD Cards, the system automatically enables the appropriate gas supplies based on their permissions. Motion sensors continuously monitor booth occupancy, and the system automatically initiates a safe shutdown sequence if a user leaves without properly closing the gas valves.

Drawing from GRIT’s proven power monitoring technology seen in their Trigger devices, the Gas Control System includes flow sensors that track gas consumption rates and patterns. This data integrates with GRIT’s comprehensive reporting system, allowing administrators to generate detailed usage reports, track consumption patterns, and manage inventory more effectively.

The system incorporates multiple safety features, including emergency manual overrides and integration with shop-wide emergency stop systems. Similar to GRIT’s existing configuration options for their Trigger devices, administrators can set specific flow rate thresholds and time-based alerts through the GRIT App interface.

For educational environments, the system provides valuable teaching opportunities by tracking student gas usage patterns and helping instructors identify potential training needs. The automatic shutoff feature adds an essential layer of safety while helping facilities reduce waste and optimize gas consumption.

FAQs about the GRIT Gas Control System:

Q: Is this system compatible with existing GRIT installations?

A: Yes, it integrates seamlessly with current GRIT Hub and Track systems.

Q: What happens during a power failure?

A: The system includes fail-safe shutoff valves that automatically close during power loss.

Q: Can different users have different gas access permissions?

A: Yes, administrators can set specific gas type permissions through GRIT Track.

Q: How does the motion detection work?

A: Advanced IR sensors monitor booth occupancy and trigger automatic shutoff when no movement is detected.

Q: What reporting capabilities are included?

A: The system provides detailed gas usage reports by user, booth, and gas type.

Q: Is manual override available?

A: Yes, emergency manual override controls are included for safety.

Q: Can the system detect gas leaks?

A: The flow monitoring system can identify unusual flow patterns indicating potential leaks.

Q: What maintenance is required?

A: Regular valve inspection and sensor calibration, similar to other GRIT devices.

Q: Is this system certified for educational use?

A: Yes, it meets all safety requirements for educational welding facilities.

Q: How does the system handle multiple gas types?

A: Each gas type has independent control and monitoring systems.

We would love the opportunity to chat about the GRIt Gas Control System with you, and how it can help create a safer and more efficient workspace for you and your students/employees. Please feel to CONTACT US and set up a time to discuss these possibilities. Thank you for your time!

—

Joel Danowitz

Co-Founder of GRIT Automation